3D printing machine have become very popular among manufacturers. The growing demand is fuelled by the numerous advantages compared to traditional manufacturing methods, and this shift is seen in many different areas of industry. Let’s see what those advantages are.

What is a 3D printing machine?

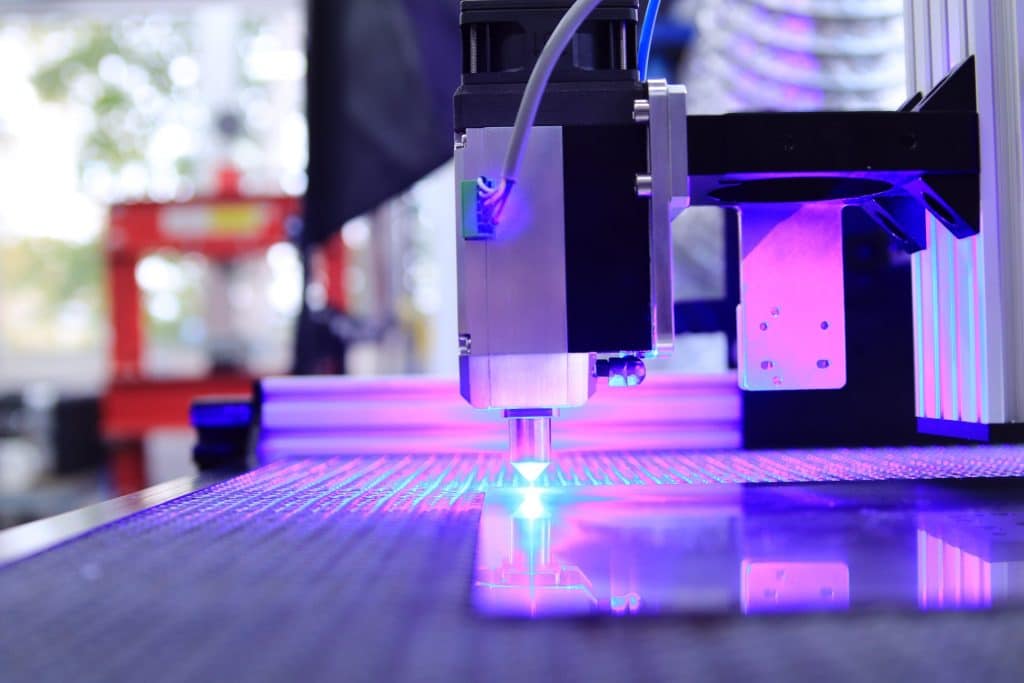

There are three main methods for taking a design from concept to a physical, three-dimensional prototype of the product. Subtractive manufacturing is a process that cuts away material from a solid block. Injection moulding, on the other hand, injects heated material into a mould. PBF additive manufacturing, best known under the name 3D printing, produces from a computer file that has been sent to a 3D printing machine, which will in turn build by adding material layer-by-layer.

Strong parts, built rapidly

A 3D printing machine manufacturer is here to offer you two options: produce parts on demand or design a 3D printing machine for you to purchase. A common process for metal 3D printing, for example, is using PBF technology (powder bed fusion), as it is an efficient way to build high-precision parts. The parts are put together layer-by-layer, a roller spreading each time a thin layer of metal powder across a build surface. The powdered material is then joined point by point using a laser beam. And the process goes on to the next layer until the part is finished. This allows for exceptional quality, great density and mechanical properties.

Flexible design and cost effectiveness

3D printing machines save time and costs. The designs can be rapidly sent and are ready for print in no time. The printing itself is done within hours depending on the parts and their design. FormUp 350 machines using PBF additive manufacturing technology have an excellent build volume with up to 4 lasers to ensure a homogenous beam on 100% of the surface. They can be used with many powders on the market, even the finest ones, and are very flexible to apply any number of design requirements. The single step process of 3D printing machines increases productivity and thus saves on costs. There is no need for operators to be present during the whole time.

3D printing machines are becoming more and more accessible because they have become widely used by various industry sectors. They are also more environmentally friendly as they have very little to no wastage. Parts can be printed on demand with no need for huge stocking areas. The prototyping process is faster and brings necessary efficiency on an industrial global stage that is ever more competitive.